Imagine a factory floor where machines don’t just work; they think, predict, and adapt. A place where production lines run 24/7 with minimal human intervention, anticipating maintenance needs before breakdowns happen and fine-tuning processes on the fly for maximum efficiency. This isn’t a futuristic fantasy—it’s the reality for manufacturers leveraging the power of AI automation today.

According to a report by McKinsey, AI-powered automation in manufacturing could increase productivity by up to 20% and lead to savings of nearly $400 billion annually by 2025. These technologies are no longer just for industry giants—74% of companies report that they plan to adopt some form of AI in their operations within the next five years.

The shift is well underway, and companies that have embraced AI automation are seeing transformative results. From predictive maintenance reducing machine downtime by 30% to AI-driven quality control systems detecting defects with near-perfect accuracy, the benefits are clear. But how exactly is AI reshaping the manufacturing landscape, and what steps should businesses take to get on board?

In this blog, we’ll explore how AI automation is revolutionizing manufacturing processes, cutting costs, boosting efficiency, and positioning companies for the future.

The Role of AI in Manufacturing

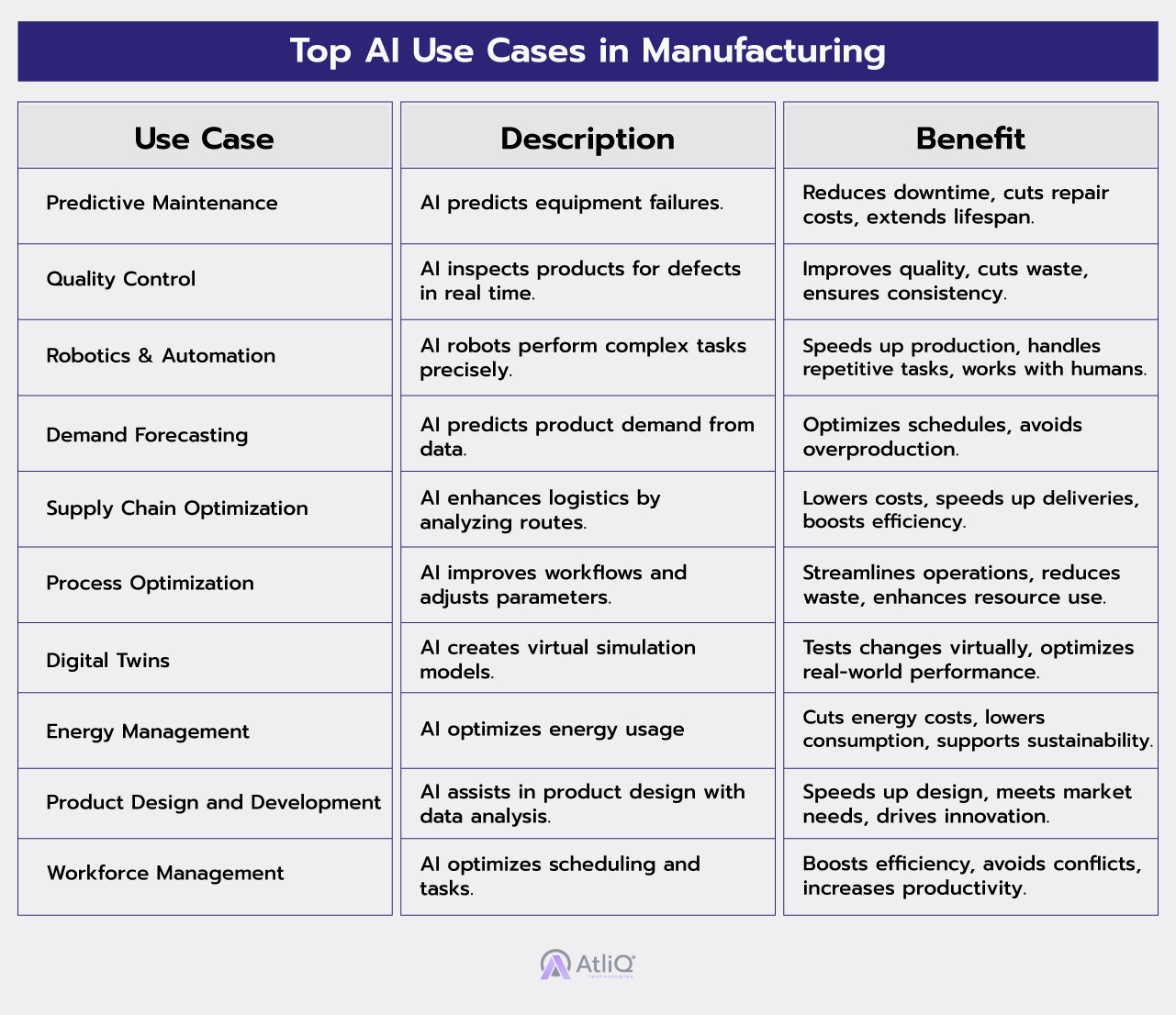

AI is revolutionizing manufacturing by automating complex tasks, optimizing processes, and enabling data-driven decision-making. Traditionally, manufacturing relied on manual labor and basic automation, but AI is now transforming operations, driving efficiency, and improving product quality.

How AI is Transforming Manufacturing?

- Predictive Maintenance: AI uses real-time data to predict equipment failures, reducing downtime by up to 30% and shifting from reactive to proactive maintenance.

- Quality Control: Machine learning and AI-powered cameras detect defects with superior accuracy, minimizing waste and enhancing product quality.

- Demand Forecasting: AI analyzes market and supply chain data to improve demand predictions, optimizing production schedules and inventory management.

- Robotics: AI-powered robots are more adaptable and precise, handling complex tasks while collaborating with human workers on assembly lines.

Key Benefits of AI Automation in Manufacturing

AI automation is reshaping manufacturing by delivering significant benefits in efficiency, cost reduction, quality, and supply chain management. Here’s a closer look at the key advantages:

-

Increased Efficiency:

AI greatly enhances efficiency by streamlining production processes, reducing downtime, and optimizing workflows. Traditional manufacturing processes often face bottlenecks caused by equipment malfunctions, human errors, or inefficient workflows. AI solves these issues by continuously monitoring operations, identifying inefficiencies, and adjusting processes in real-time.

- Reduced Downtime: AI-powered systems can predict potential equipment failures before they happen, scheduling maintenance during non-productive hours to avoid halting production. This ensures that machines are operational for longer periods, increasing overall productivity.

- Faster Production: AI automates repetitive and time-consuming tasks, allowing machines to work faster and more precisely than humans. This results in shorter production cycles and higher throughput.

- Workflow Optimization: AI algorithms analyze production data to optimize workflows. They can automatically adjust variables like production speed or resource allocation, ensuring that processes are running at peak efficiency.

-

Cost Reduction:

AI-driven automation significantly lowers operational costs by reducing waste, improving accuracy, and minimizing human error. Every step of the manufacturing process, from raw material usage to final product inspection, can be optimized using AI to minimize costs.

- Minimizing Waste: AI systems monitor production lines in real time, identifying inefficiencies that lead to material waste. For example, AI can precisely control material input to ensure optimal usage, preventing excess waste.

- Improved Accuracy: AI-powered machines are more precise than human workers, reducing the chance of production errors that lead to rework or product recalls. This accuracy saves costs associated with defective products and increases customer satisfaction.

- Fewer Human Errors: Automation reduces reliance on manual labor for repetitive tasks, minimizing the likelihood of mistakes. Human errors, such as incorrect assembly or improper machine calibration, are reduced when machines handle these tasks.

-

Predictive Maintenance:

Predictive maintenance is one of the most valuable applications of AI in manufacturing. Traditional maintenance schedules often lead to unnecessary downtime or unexpected machine failures, both of which can be costly. AI shifts maintenance from reactive to proactive by predicting when equipment is likely to fail based on real-time data.

- Accurate Forecasting: AI uses data from sensors and historical patterns to predict equipment failures before they occur. This allows manufacturers to schedule maintenance at optimal times, preventing costly breakdowns and reducing the need for emergency repairs.

- Extended Equipment Lifespan: By addressing potential issues early, predictive maintenance extends the lifespan of machines, reducing the need for frequent replacements and lowering long-term capital expenditures.

-

Improved Quality Control:

AI plays a critical role in real-time monitoring and defect detection, ensuring that only high-quality products make it through the production line. With traditional quality control methods, human inspectors often miss defects or inconsistencies, leading to subpar products. AI-powered quality control systems solve this problem by providing more accurate and faster inspections.

- Real-Time Defect Detection: Using machine vision and deep learning algorithms, AI systems can monitor production in real-time, instantly identifying defects that are invisible to the human eye. This allows manufacturers to fix issues immediately, preventing defective products from reaching customers.

- Consistency and Precision: AI systems are capable of ensuring consistent quality by checking each product against a set of predefined criteria. This reduces variability in production and ensures that every product meets the same high standards.

-

Enhanced Supply Chain Management:

AI doesn’t just optimize internal manufacturing processes; it also transforms supply chain management by improving demand forecasting, inventory management, and logistics.

- Demand Forecasting: AI analyzes market data, customer behavior, and external factors like seasonality or economic conditions to predict demand more accurately. This ensures that manufacturers produce the right amount of goods, reducing overproduction and stock shortages.

- Inventory Management: AI-powered systems automatically monitor stock levels and usage patterns, ensuring optimal inventory levels at all times. By reducing excess inventory or preventing stockouts, AI helps manufacturers save on storage costs and meet customer demand more efficiently.

- Logistics Optimization: AI optimizes transportation and logistics by analyzing routes, traffic, and weather patterns. This ensures faster, more efficient deliveries, reducing shipping costs and ensuring that materials and products arrive on time.

AI automation is transforming manufacturing by enhancing efficiency, reducing costs, enabling predictive maintenance, improving quality control, and optimizing supply chains. The adoption of these technologies allows manufacturers to stay competitive, increase output, and adapt to an ever-changing market environment.

Challenges of Implementing AI in Manufacturing

- High Initial Investment and ROI Considerations

-

-

- Challenge: Significant upfront costs for AI technology, infrastructure, and integration.

- Impact: Extended time to realize return on investment (ROI) and potential budget constraints.

-

- Integration with Legacy Systems and Workforce Training

-

-

- Challenge: Difficulties integrating AI with existing legacy systems and processes.

- Impact: Requires substantial modifications and investments, along with comprehensive training for the workforce.

-

- Data Privacy and Cybersecurity Concerns

-

- Challenge: Ensuring the protection of sensitive data and safeguarding against cyber threats.

- Impact: Necessitates robust cybersecurity measures and compliance with data privacy regulations.

These challenges highlight the complexities involved in adopting AI in manufacturing, requiring careful planning and investment to overcome.

The Future of AI in Manufacturing

The future of AI in manufacturing promises transformative advancements that will reshape the industry. Here are key trends and developments to watch:

- Advanced Automation: AI will drive more sophisticated automation, integrating robotics and machine learning to handle increasingly complex tasks, leading to smarter and more efficient production lines.

- Enhanced Predictive Analytics: Future AI systems will offer even more accurate predictive analytics, allowing manufacturers to foresee equipment failures, optimize maintenance schedules, and adjust production in real time.

- Integration with IoT and 5G: The combination of AI with Internet of Things (IoT) devices and 5G technology will enable faster, more reliable data transfer, enhancing real-time monitoring and control of manufacturing processes.

- Personalized Manufacturing: AI will facilitate mass customization by using data to tailor products to individual customer preferences, enabling manufacturers to meet specific demands efficiently.

- Sustainable Practices: AI will support sustainability by optimizing energy usage, reducing waste, and improving resource management, helping manufacturers meet environmental goals.

- Human-Machine Collaboration: The future will see greater collaboration between AI and human workers, with AI handling repetitive tasks and humans focusing on complex problem-solving and creative tasks.

Related: Innovative Solutions: AI Automation and Manufacturing Efficiency

As AI technology evolves, it will continue to drive innovation in manufacturing, making processes more efficient, flexible, and sustainable.

AI is revolutionizing the manufacturing industry, offering unprecedented opportunities for efficiency, cost reduction, and innovation. From predictive maintenance and quality control to supply chain optimization and real-time process monitoring, AI is transforming every aspect of production. However, challenges like high initial investment, integration with legacy systems, and data privacy concerns must be carefully navigated.

As AI technology continues to advance, the future of manufacturing will be defined by smarter automation, enhanced predictive capabilities, and more sustainable practices. Companies that embrace AI now will be better positioned to lead in this rapidly evolving landscape, gaining a competitive edge while shaping the future of manufacturing.

Take the First Step to Smarter Manufacturing – Let’s Talk AI!